About Platex®India

20 Years of Experience in Heat Exchangers and Allied Products

Platex®India is a proprietary firm established in 2018 by professional with more than 20 years of experience in heat exchanger and allied products. Objective of starting Platex®India was to provide after sales support i. e. Service and Spares support to the customers.

In a very short period, Platex®India is being one of the prominent brand in the heat exchanger market due to its cost effective, quick and reliable service support.

Service team of 30+ engineers and technicians, two renowned service centers at Pune, Maharashtra and Belgaum, Karnataka, 24X7X365 days service support, specially designed service van for On-Site Servicing …

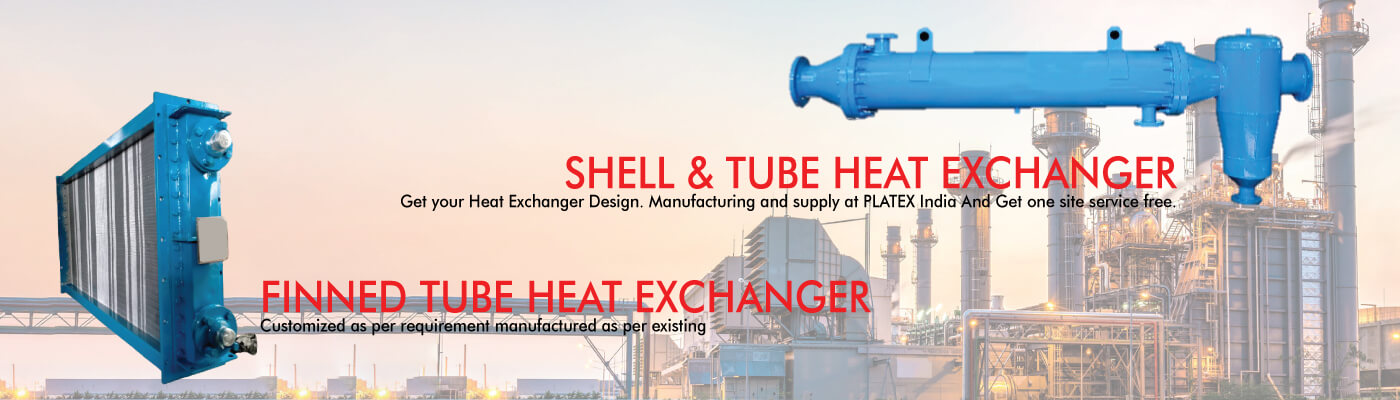

Products Range

A heat exchanger is a system used to transfer heat between two or more fluids. Heat exchangers are used in both cooling & heating processes. The fluids may be separated by a… Read More

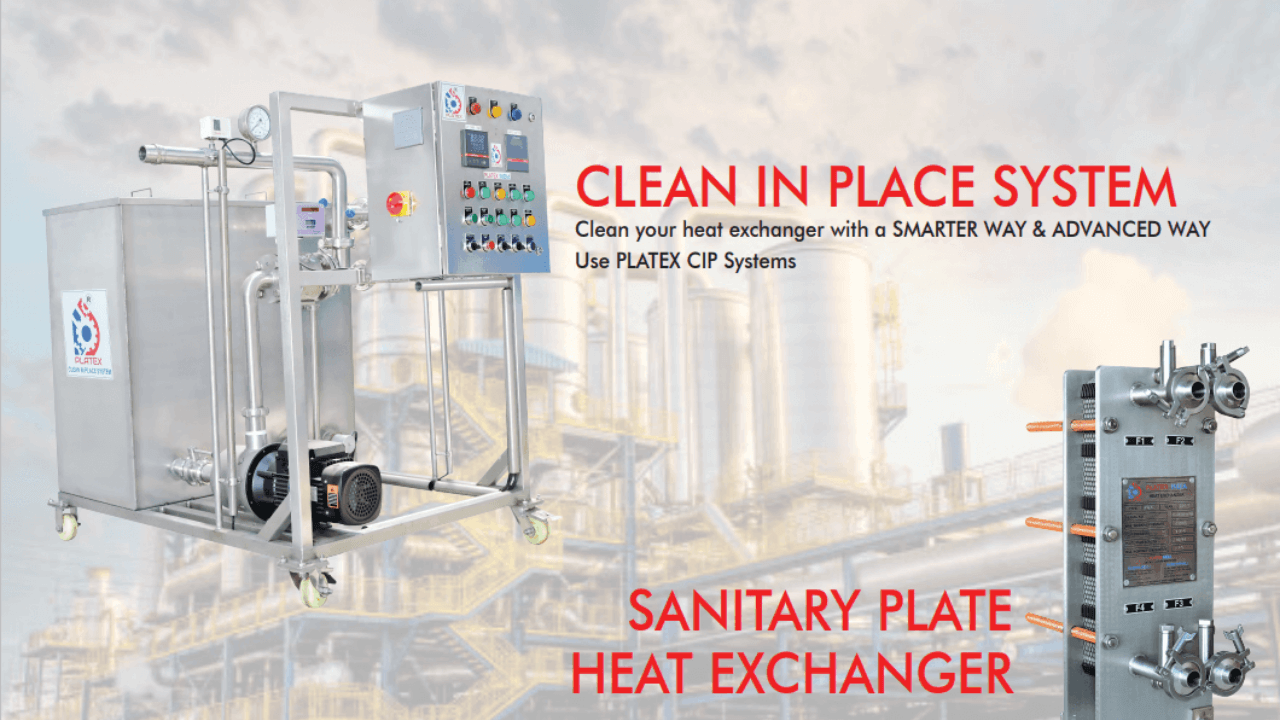

Clean-In-Place (CIP) systems are automated systems used to clean the interior surfaces of Heat Exchangers, process pipes, vessels, tanks, spiral freezers, mixers, blenders… Read More

Bulk milk cooling tank, also known as a bulk tank or milk cooler, consists of an inner and an outer tank, both made of high quality stainless steel. The space between the outer tank & the… Read More

Hot Water Generation System

Platex®India HWS is used to heat the water indirectly by steam & most efficient way for instant hot water generation for process industries, compact, preassembled skids designed… Read More

An evaporative condenser is combination of Cooling Tower & Condenser which is used to remove excess heat from a cooling (Refrigeration) system when the heat can’t be utilized.… Read More

Small Scale Coil Type Evaporation System

A Conventional evaporation is headed steam which condenses & transmits heat energy to the solution to be evaporated. As this solution boils it in turn releases vapor which may: Either be… Read More

Platex®India Unique Water solutions is Anti scaling & descaling mechanical equipment and can be installed in Domestic, Agriculture & Industrial application before the heat Exchangers. Condensers, chilling plants, boilers, humidification plants to avoid scale formation in this equipment & it helps in descaling in pipes if scales already exist. IMPULSE WITH ELECTROLYSIS technology makes it more competitive to make the water cohesive & results in to scale removal in… Read More

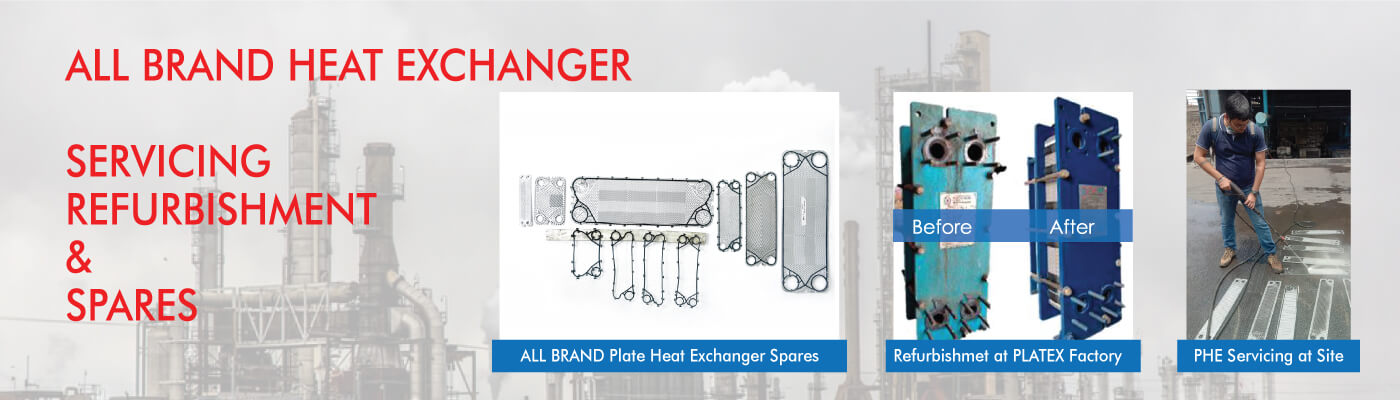

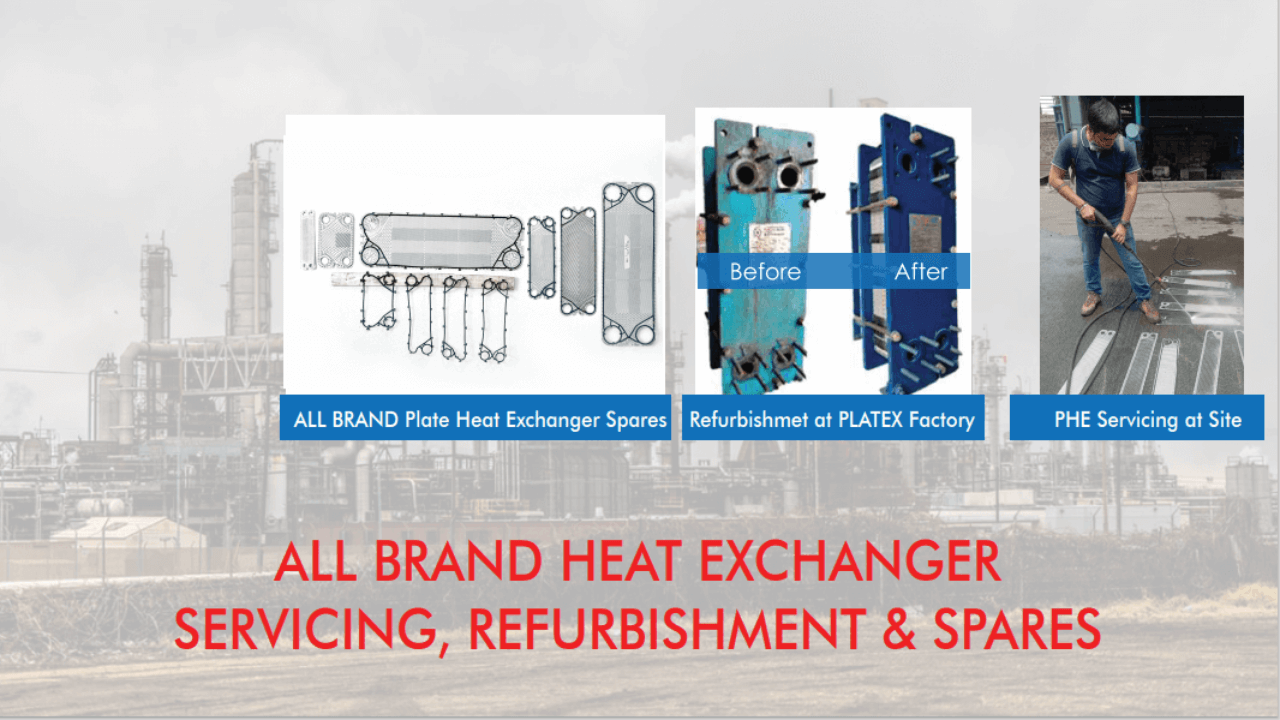

Services

Platex®India has got a team of experienced professionals, who can repair heat exchangers at site & Well equipped factory of Platex®India is ready for refurbishment of heat Exchangers.

-

On site servicing of Heat Exchangers

-

Refurbishment of All types of Heat Exchangers at our factory

-

Annual Maintenance contracts for all the Heat Exchangers in Plant with Spares inventory in Platex®India Scope

-

Condenser / Evaporator cleaning

-

Retubing of Shell & Tube and Fin Tube Heat Exchanger

-

Tube Bundle replacement

-

Field auding for Thermal efficiency

Some Cool Facts

Numbers Speak For Themselves

Partnered With