Heat Exchanger Services

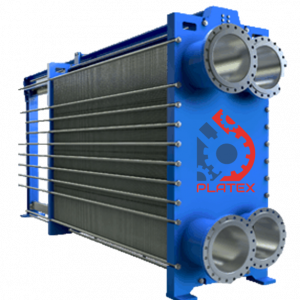

Heat Exchanger Spares & Servicing by Platex®India

The installation of the India’s most modern plate heat exchanger reconditioning center in Pune is an exciting development for Platex® & our customers. We’re able to offer our customers a full range of services across the India, Middle East, South East Asia & Africa.

- Supply of all brand PHE Spares

- Servicing of all brand PHE

- Refurbishment of All brand PHE

- Repair of Shell & Tube Heat Exchanger

- 24 X 7 X 365 days emergency telephonic support for break-down

- Experienced service technicians

- Cure leaks, reduce production losses

- Rapid turnaround to minimize production disruption,

- 100% performance by restoring heat transfer & pressure drop

- Minimize the risk of unscheduled productions stops

Heat Exchanger Spares by Platex®India

Platex®India is a stocking distributor of Plate Heat Exchanger spares

- Gaskets – NBR, EPDM, Viton

- Heat Transfer Plate – SS304, SS316, Titanium Grade – 1 , Titanium Grade – 11, Hast-alloy C276, C22 Etc.

We also engineer,

- Heat Exchanger Performance,

- Thermal Rate

- Capacity Expansion,

- Servicing of heat Exchangers

We have been stocking and selling plate heat exchanger gaskets and heat exchangers regularly to domestic as well as international market. We’re able to offer our customers a full range of services across the India, Middle East, South East Asia & Africa.

All Services

Inspection of PHE

- Frame Inspection for rusting, Foundation etc.

- Inspection of PHE for Side Leakages, Misalignment in Honeycomb Pattern etc.

Identify & Inspect Plates

- Once plates arrive for refurbishment they are identified and logged.

- All gaskets are then carefully removed from the plates.

Dismantling of PHE

- Carefully dismantling PHE, without damaging the threading of studs & affecting rollers.

- Inspection of Frame Plate (Front Plate) & Pressure Plate (Back Plate) for any damage

- Inspection of stainless Steel Liners at Inlet & Outlet of the PHE Frame

Chemical Cleaning

- Testing the soil on the Plate

- Identifying The suitable descaling solution

- Plate soaking in descaling solution bath

- Cleaning with soap solution

- Plates are chemically cleaned.

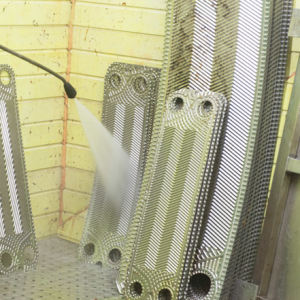

Rinsing & Drying

- Rinsing the Plates

- Cleaning the Plates with high pressure jet wash

- Drying the Plates

Frame Cleaning

- Frames are washed properly, Frame Plate (Front Plate) & Pressure Plate (Back Plate).

- Inner sides of the frames Frame Plate (Front Plate) & Pressure Plate (Back Plate) are cleaned.

Visual Inspection & Die Penetration Testing

- Inspection of each heat Transfer plate visually for any cracks, dent marks, pin holes

- Application of red die penetrant on one side of the heat transfer plate

- Application of white developer on the another side

- DP testing is most proved method of identifying cracks & Pin holes

- Marking the pin holes found on the HT Plates with marker

- Rinsing the plates with water

Gasket - Plate Assembly & Plate Pack

- After Inspection & identification of rejected HT Plates, Acceptable plates are taken for re-gasketing.

- Following inspection, new gaskets are clipped or bonded to the refurbished plates.

- Appropriate adhesives are used where required.

- All plates are clamped to ensure correct alignment.

- Plates are arranged as per Flow pass arrangement ensuring Honey Comb Pattern

- Complete pack of all the plates as per design is prepared ensuring all channel flow, passes & Honey comb pattern.

Light Box Testing

- Testing the HT Plates in dark room with a UV light on another side of the Plate

- This visualizes smallest pin hole or crack.

- Light box testing is cost effective method of identifying damaged HT Plates.

Assembly of PHE

- Plate Pack is inserted between Frame Plate (Front Plate) & Pressure Plate (Back Plate)

- Tightening of Studs is been carried out carefully ensuring cross tightening.

- Pack length of PHE is been maintained.

Hydrostatic Testing of PHE

- After Assembly of PHE, again visual Inspection is done for ensuring fitment

- PHE has been performed pressure-leak test before taking for operation.

- In case of hydrostatic test, Pressurize hot and cold side independently and/or both sides at the same time.

- Actual test pressure shall not exceed the specified test pressure.

- Over test pressure could result in heat transfer plate/frame deformation and/or leaking.

- The test pressure is referred to Plate Arrangement Drawing.

Inspection Report & PHE Handover

- After successful Hydrostatic testing of PHE, Inspection report is prepared for all the activities carried out & replacement of spares, rejection of plates etc.

- Inspection report & PHE testing approval is taken from customer before handover of PHE

- After confirmation & satisfaction, PHE is handed over to customer.