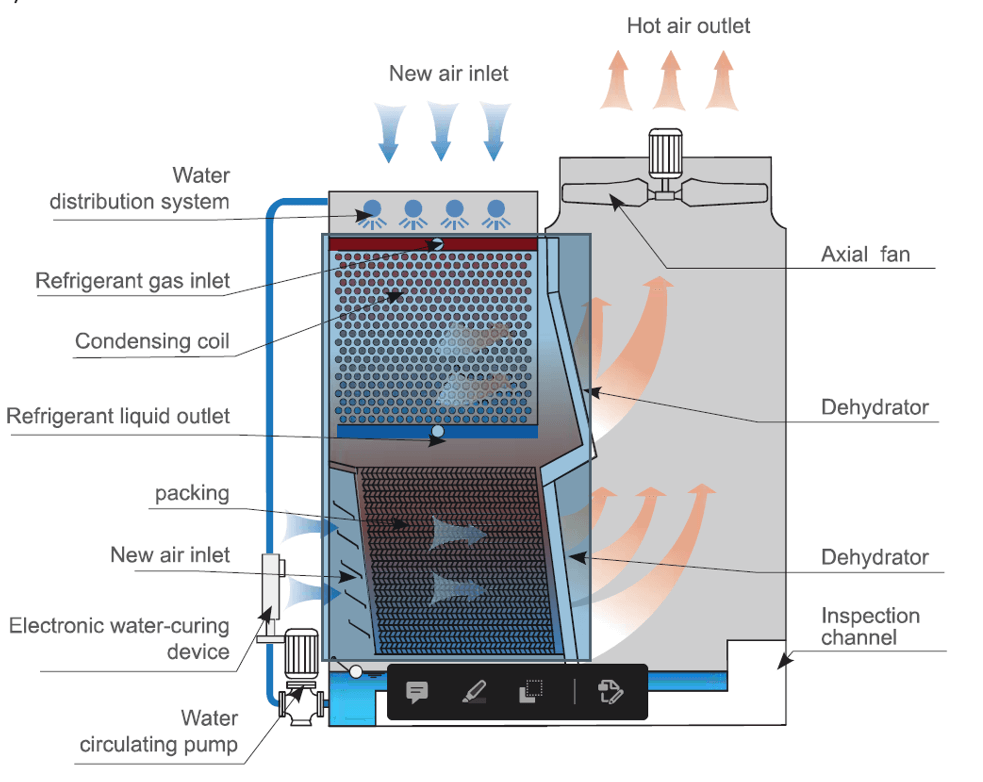

Evaporative Condenser

An evaporative condenser is combination of Cooling Tower & Condenser which is used to remove excess heat from a cooling (Refrigeration) system when the heat can’t be utilized for other purposes. Platex®India has wide range of customized designs for evaporative condenser starting from 80TR to 1000TR range. Platex®India has installed 48+ Evaporative condensers with yearly service contract.

Principle of Operation

- The PLATEX® use combined flow technology, which improves the efficiency of evaporation and cooling, also reduces water wastage.

- The refrigerant is circulated through the coil of the evaporative condenser. Heat from the refrigerant is dissipated through the coil tubes.

- Water is sprayed in parallel with the fresh ambient air flowing over the outside of the condensing coil.

- Parallel air and water paths minimize scale producing dry spots that may be found on the bottom of the tubes in other conventional condensers.

- The condensing coil rejects heat through both evaporative cooling using the fresh air stream and, more significantly, through sensible cooling of the pre-cooled recirculating spray water.

- Reducing this evaporative cooling component from the coil section helps to minimize the formation scale on the coil surface.

- A portion of this evaporated heat is discharged sideways to atmosphere by the downward natural induced air.

- The warm moist air is drawn sideways by the fan and is discharged to the atmosphere. The remaining water falls from the coil to the fill surface section where it is cooled by a second fresh air stream using evaporative heat transfer and eventually to the sump at the bottom of the condenser where it is recirculated by the pump up through the water distribution system and back down over the coils.

Components of EVC

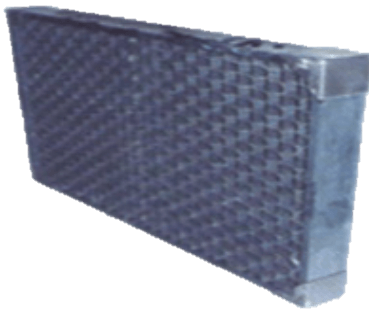

Condensing Coil

- Exclusive condensing coils are manufactured from high quality steel tubing following the most stringent quality control procedures. Each circuit is inspected to assure the highest material quality.

- All coils are formed in one continuous piece using a unique automatic coil production line, this process limits welding slag, increases production efficiency and factory lead times.

- The coils are hydrologically tested 3 times during the manufacturing process to 2.5Mpa to ensure they are leak free.

- To protect the coil against corrosion, coils are placed in a heavy steel frame and then the entire assembly is dipped in molten zinc (hot-dip galvanized) at a temp of 450˚C .

- The tubes are pitched in the direction of fluid flow to provide good liquid drainage.

Fill Technology

- Fills design used in the evaporative condensers and cooling towers are specially designed to induce highly turbulent mixing of the air and water for superior heat transfer.

- Special drainage tips allow high water loading without excess pressure drop.

- The fill is constructed of inert polyvinyl chloride (PVC) which will not rot or decay and is formulated to withstand water temperatures of 55 Degree Centigrade.

- Due to the unique way the cross-fluted sheets are bonded together in the honeycomb structure of the fill and the bottom support of the fill section, the structural integrity of the fill is greatly enhanced, making the fill usable as a working platform.

- The fill selected for the condenser and cooling tower has excellent fire resistant qualities.

Advanced Technology—

De-scaling Cleaner

- The electronic De-scaling cleaner offers 98% increased effectiveness over of water scale inhibition

- over 95% increased sterilization & algae removal over high- frequency electronic technology.

- Designed especially for closed loop cooling towers and evaporative condensers with low power consumption.

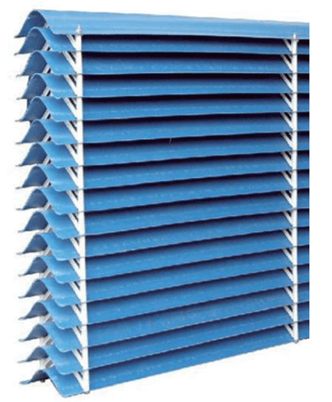

Air Inlet Louver

- With the two pass louver system, the water droplets are captured on the inward sloping pass, minimizing splash-out problems.

- Unique louver design for all evaporative condensers & closed loop cooling tower lines completely encloses the basin area.

- Direct sunlight is blocked from the water inside the condenser and cooling tower, thereby reducing the potential of algae formation.

- Water treatment and maintenance costs are substantially reduced.

- While effectively containing the recirculating water and blocking sunlight, the louver design has a low pressure drop.

- The low pressure drop results in lower fan energy consumption, which reduces the operating costs of the cooling tower.

Pressurized Water Distribution System

- Exclusive Maintenance free spray nozzle remains clog-free while providing even and constant water distribution for reliable, scale-free evaporative cooling under all operating conditions. Furthermore, the nozzles are mounted in the corrosion-free water distribution pipes and have threaded end caps.

- Together, these elements combine to provide unequaled coil coverage and scale prevention, which makes them industry’s best performing non – corrosive, maintenance-free water distribution system.

Metal Air Deflector

- With adjustable air deflector system, the water droplets are captured on the inward sloping pass, minimizing splash-out problems.

- It’s unique design for all evaporative condensers and closed loop cooling tower lines completely encloses the basin area.

- Adjustable function keeps direct sunlight away from the water inside the condenser and cooling tower, thereby reducing the potential of algae formation.

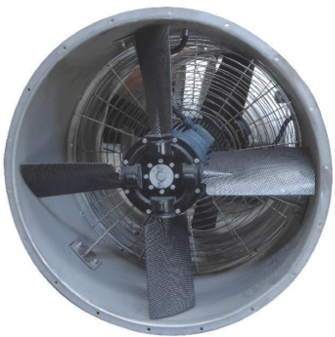

Direct Drive Axial Fan

- Direct drive fans offer following advantages over belt driven fans: 1) Low failure rate 2) Easy maintenance 3) Low noise 4) Low transmission loss

- The axial fan use specific carbon fiber blades forward curved fan, this offers, high air volume, low noise, perfect performance with high efficiency.

Other Components & Benefits

- Low Maintenance

- Sloping Basin: The slope of basin bottom to drain pipe makes for convenient cleaning and removal of debris.

- Large Access Doors: Large access doors and generous inner chamber makes for convenient examination and repair.

- The ball cock and filter can be examined and repaired without stopping the operation of the condenser due to the same direction for airflow and water flow.

- The nozzles and coils also can be examined and repaired during operation.