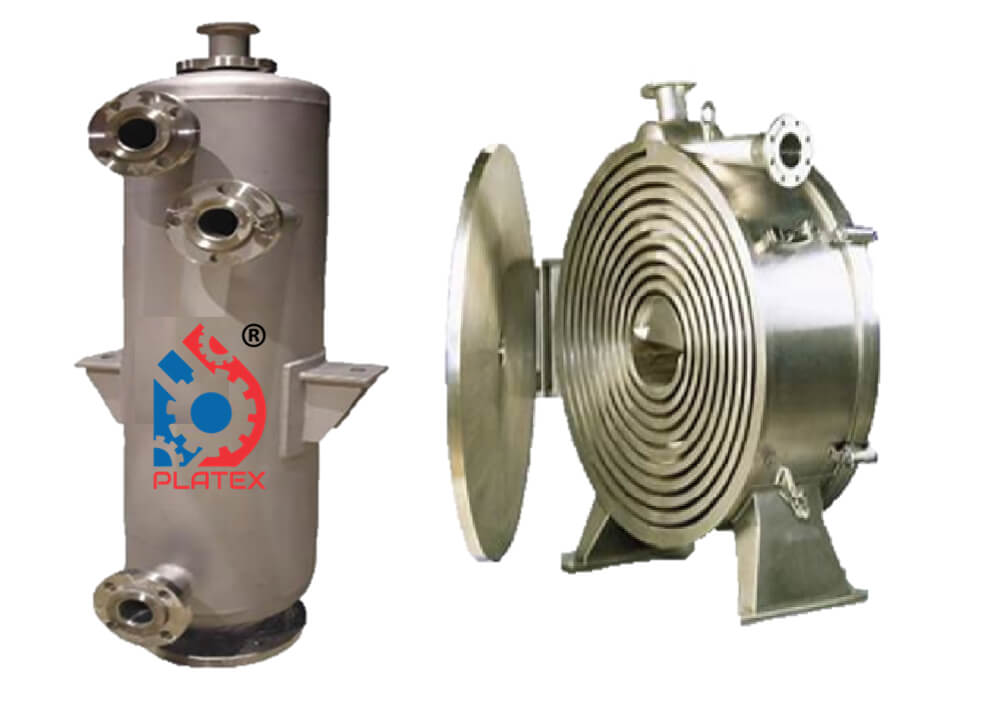

Spiral Heat Exchanger

Solvent Condenser

- Key equipment for recovering expensive solvents from reactors

- Platex®India SHELIX offers compact & optimized design for atmospheric & vacuum duties with maximum solvent recovery

- Platex®India offers highly efficient spiral condensers to be used as primary/Secondary & Vent Condensers in API/ Bulk Drug Industries

- Special applications like reboiler & Full/Partial evaporation are available

Reactor Mass Cooling With Platex®India Spiral Heat Exchanger

Reactor Capacity – 1.5KL

- Synthetic Oil is in closed Circuit used to cool the reactor mass.

- Synthetic Oil to be cooled down from 220°C to 40°C in two stages.

- Stage 1: To be cooled down of 220°C Oil to 80°C using 70°C Water.

- Heat Load – 150,000 Kcal/h (max) Batch Time – 45 min

- Stage 2: To be cooled down of 80°C Oil to 40°C using 25°C Water.

- Heat Load – 35,000 Kcal/h (max) Batch Time – 30 min

Typical Pharmaceutical Application For Solvent Recovery

Benefits:

- Sturdy & Compact design for both, atmospheric & vacuum duty

- Above 95% solvent recovery compared to a conventional HE

- Single Pass flow avoids clogging on utility side

- Easy installation & operation

- Smaller foot print reduces heavy structure for support compared to conventional HE

- Eliminates use of expensive utility due to close temperature approach.