About Platex®India

20 Years of Experience in Heat Exchangers and Allied Products

Platex®India is a proprietary firm established in 2018 by professional with more than 20 years of experience in heat exchanger and allied products. Objective of starting Platex®India was to provide after sales support i. e. Service and Spares support to the customers.

Innovative designs, one to one replacement solutions have made Platex(R) stand apart from other major players. along with heat exchanger the biggest service network makes us first choice of customers who believe in made in India products. All brand PHE spares is an added advantage for customer who wants one stop solution.

In a very short period, Platex®India is being one of the prominent brand name as heat exchanger manufacturer and in market due to its cost effective, quick and reliable service support.

Service team of 30+ engineers and technicians, two renowned service centers at Pune, Maharashtra and Belgaum, Karnataka, 24X7X365 days service support, specially designed service van for On-Site Servicing …

Product Range

A heat exchanger is a piece of equipment that transfers heat from one medium to another. The design of a plate heat exchanger (PHE) comprises numerous heat transfer plates called as plate pack kept together using two plates called as Frame and Pressure Plate. Each heat transfer plate has a gasket arrangement, which defines flow and providing two separate channel systems.

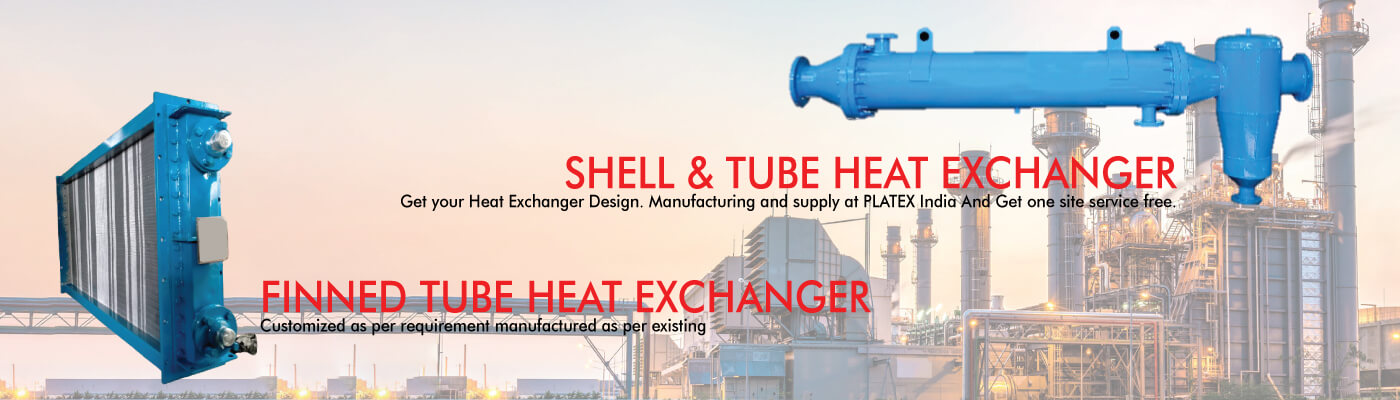

Shell and Tube Heat Exchangers (STHE) are most conventional engineering equipment and working principle is as per TEMA guidelines, which is the proven and widely accepted norm. We understand customers specifications for requirements of thermal design and equipment proposed precisely suited for the process.

Platex®India HWS is used to heat the water indirectly by steam & most efficient way for instant hot water generation for process industries, compact, preassembled skids designed

A Conventional evaporation is headed steam which condenses & transmits heat energy to the solution to be evaporated. As this solution boils it in turn releases vapor which may: Either be

Finned tube heat exchangers generally use air to cool or heat fluids such as air, water, oil or gas, or they can be used to capture or recover waste heat. Two phase application is beauty of this heat exchanger. These heat exchangers can used in a broad range of industries including oil & gas, power generation, marine and HVAC.

BPHEs (Brazed Plate Heat Exchangers) consist of corrugated plates that form channels for hot and cold fluids to flow in opposite directions. These compact, efficient units require no maintenance and are ideal for heating, cooling, evaporation, and condensing in various applications. They are designed for optimal performance, featuring unique attributes that enhance thermal efficiency and reliability, ensuring a long service life even under high pressure conditions.

Spirals are Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibres and solids, EHTS spiral heat exchangers are the ultimate solution for applications that require treatment of challenging fluids. Spiral Heat Exchangers (SPHE) which are compact in size and 3 times more thermally efficient than conventional heat exchangers, The counter-current flow design makes it possible to achieve very close temperature approaches.

Block and tube heat exchangers transfer heat between two fluids without direct contact. Comprising a stack of tubes housed in a steel shell, these devices utilize a combination of square blocks and tubes made from various materials of construction (MOC). Heat is transferred through the material separating the mediums in the rows of holes. Their modular design allows for easy maintenance and expansion, enhancing versatility and efficiency in thermal management.

PLATEX Heat Exchanger Systems are designed to deliver optimal performance across multiple industries, including Pharmaceutical, Chemical, Oil and Gas, Food and Beverage, and HVAC. These systems enhance efficiency and reliability, catering to the specific thermal management needs of each sector. PLATEX provides customized skid- mounted heat exchanger-based systems (HES) that serve as innovative heat transfer solutions for key thermal applications across various process industries. These skids are designed to complement the main process plant, enhancing overall efficiency and performance in thermal management.

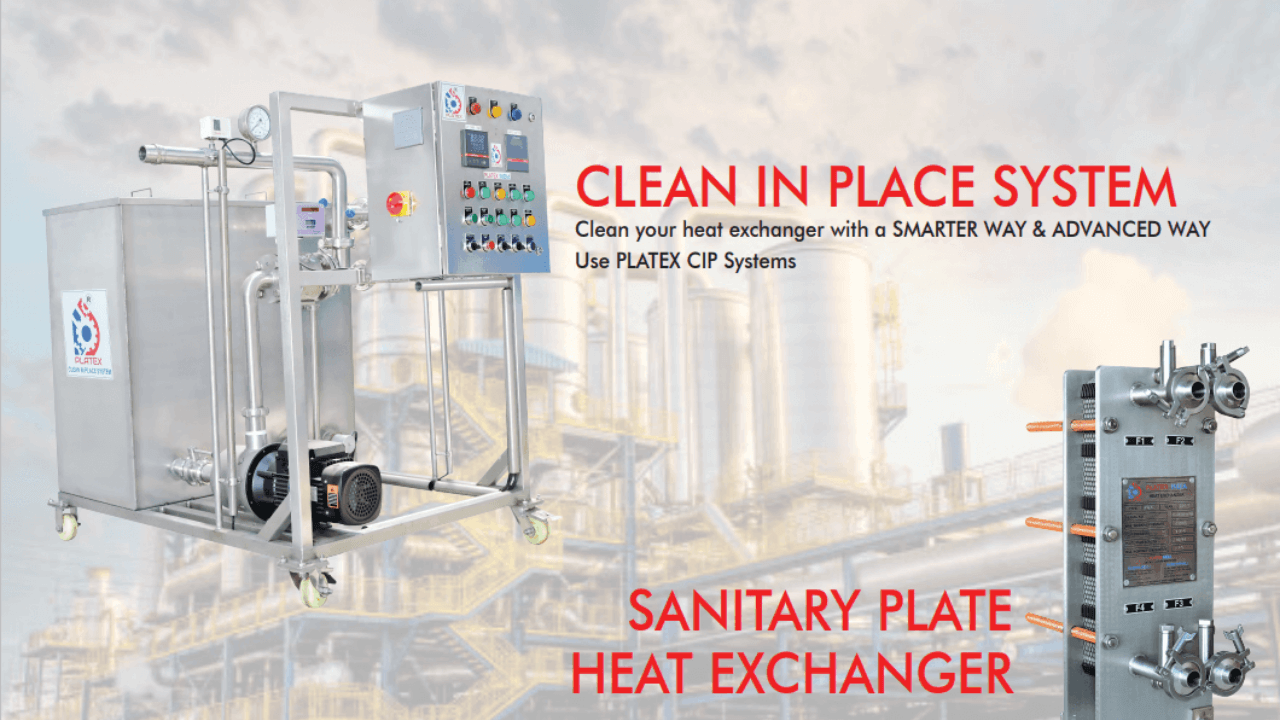

When fouling occurs, the Platex Mobile Trolley Mounted CIP (Clean-In-Place) System allows for quick and easy in-line cleaning of heat exchangers without the need to dismantle equipment. Additionally, Platex can design custom CIP solutions tailored to specific needs, such as large heat exchanger installations or areas requiring explosion – proof equipment for safety. By eliminating the need for repeated and unnecessary equipment openings, you significantly reduce spare parts consumption and the man-hours needed for cleaning. This not only enhances operational efficiency but also lowers maintenance costs.

A Small Effluent Treatment Plant (ETP) is a vital system used in industries to treat and purify wastewater before environmental discharge. Designed for smaller volumes from businesses or residential communities, a Small ETP Plant employs various processes to effectively remove contaminants, ensuring the water is safe for discharge or reuse. These processes may include physical, chemical, and biological treatments, tailored to meet the specific needs of the wastewater.

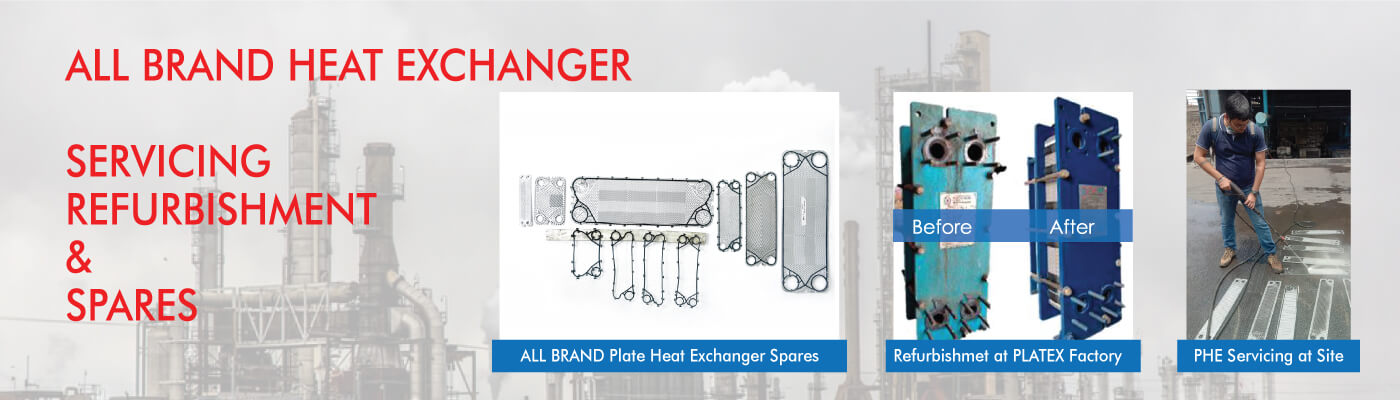

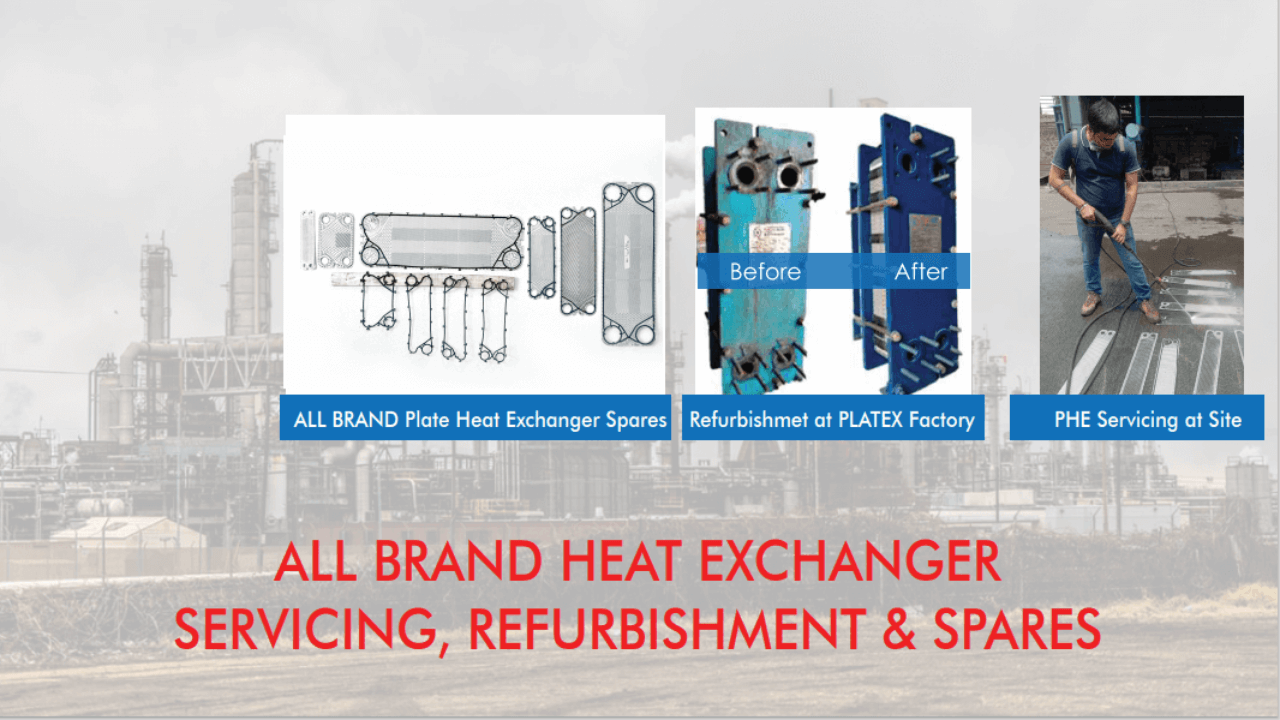

We offer genuine spare parts and on-site service for all reputable brands of plate heat exchangers, ensuring reliable maintenance and support for your equipment. Our technical specialists are equipped to refurbish all brands of plate heat exchangers, whether in our shops or on-site at your facility. We specialize in multi-brand plate heat exchangers, including wide gap, normal gap, and brazed types, and we stock a variety of spare parts. We offer OEM parts, gaskets, and plates made from materials like 316 stainless steel, titanium, and various grades of HASTELLOY or SMO. Our services ensure high-quality maintenance and spare parts for any make of plate heat exchangers.

Services

Platex®India has got a team of experienced professionals, who can repair heat exchangers at site & Well equipped factory of Platex®India is ready for refurbishment of heat Exchangers.

-

On site servicing of Heat Exchangers

-

Refurbishment of All types of Heat Exchangers at our factory

-

Annual Maintenance contracts for all the Heat Exchangers in Plant with Spares inventory in Platex®India Scope

-

Condenser / Evaporator cleaning

-

Retubing of Shell & Tube and Fin Tube Heat Exchanger

-

Tube Bundle replacement

-

Field auding for Thermal efficiency

Some Cool Facts

Numbers Speak For Themselves

Partnered With